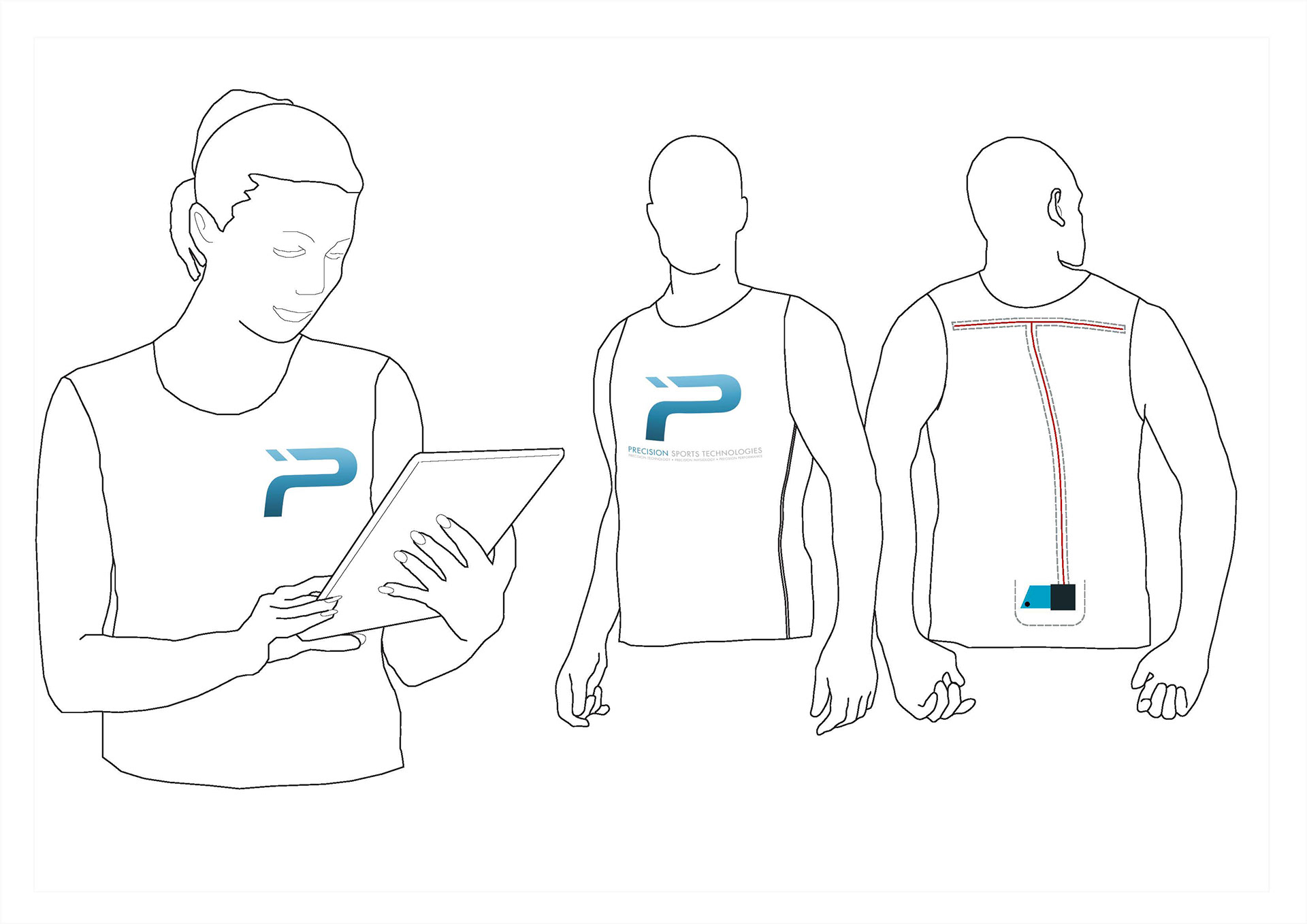

Precision AMS. Athlete Sports Monitoring System

Precision Sports Technologies Ltd

Existing Product Audit; User Centred Research; Funding Application Support; Concept Design; Concept Models; Ergonomic Assessment: Electronics Integration; Test Rig Prototypes; Pre-Production Prototypes;

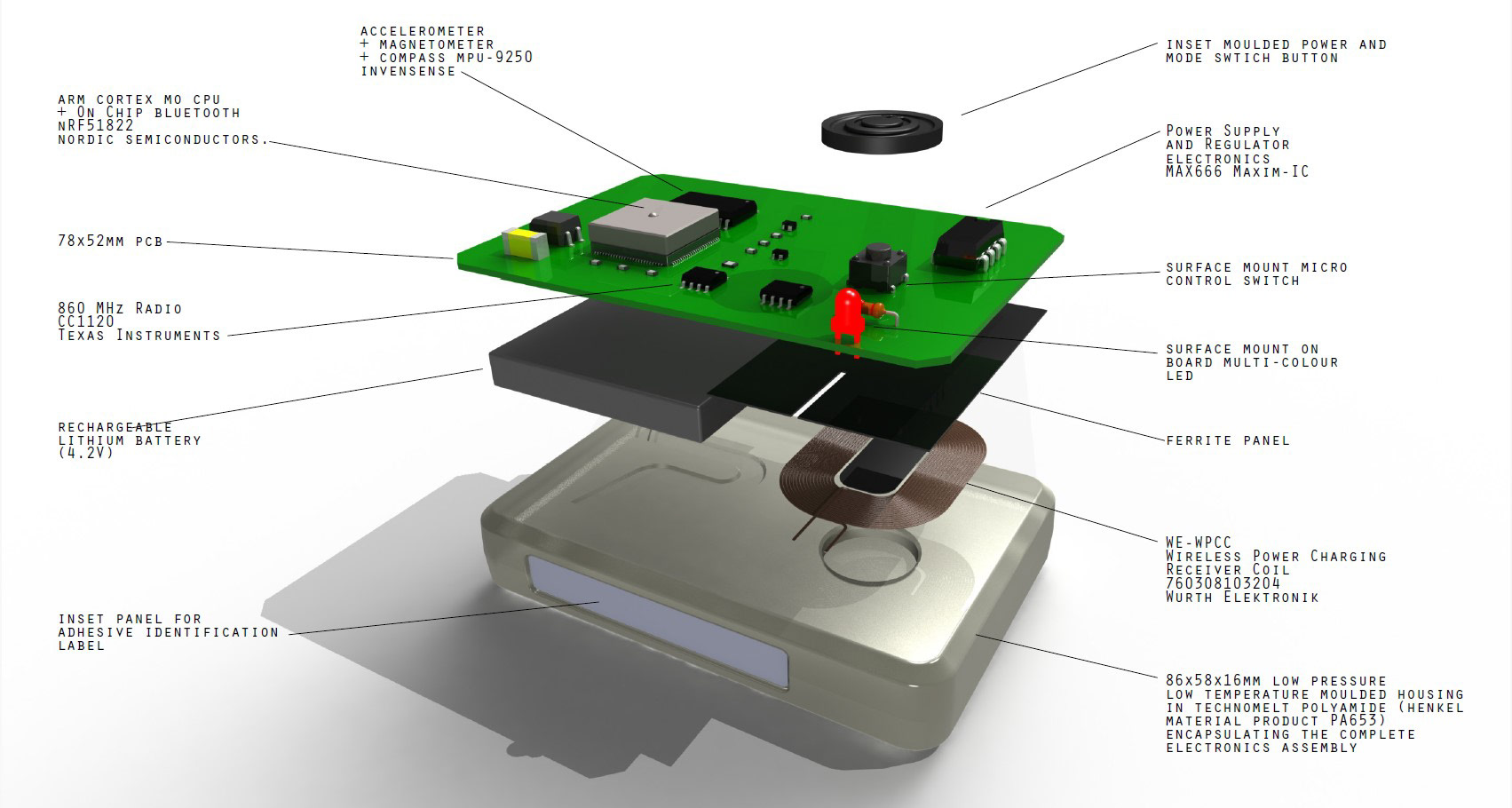

SolidWorks CAD full assembly model production engineered for low volume RIM moulding and low pressure/temp encapsulation

SolidWorks CAD full assembly model production engineered for low volume RIM moulding and low pressure/temp encapsulation

Design and development of the Precision Athlete Monitoring System for start-up Precision Sports Technologies Ltd. The solution progressed through a series of concept designs to a fully functional set of working samples fabricated from RIM moulding. The final production specification would be based on low pressure encapsulation moulding, which completely over moulds the electronic components in a single shot, providing the highest of ingress protection (IP).

With Bluetooth and radio connectivity, coil based contactless rechargeable battery management and a translucent polymer material allowing LED status indication, there would be no need for a physical contact to the electronics.

With Bluetooth and radio connectivity, coil based contactless rechargeable battery management and a translucent polymer material allowing LED status indication, there would be no need for a physical contact to the electronics.

Initial concepts were worked up to enable physical 'dumb' prototypes to be printed and assessed for form and function, with concepts around charging possibilities for a team or squad with up to 30 units charged simultaneously visualised. A set of units were fabricated and assembled for test, along with the associated software and ariel receiver. These were trialled in the field with a professional football club. They consisted of a reaction injection moulded clamshell and full functioning electronics. Further units were trialled with other professional athletes and the solution became the subject of a Kickstarter campaign to secure production revenue.

Marylin Onyoko testing the prototype